Greenhouse curtains provide essential climate control and crop protection for commercial growing operations across Ontario. These automated greenhouse curtain systems help growers manage light levels, temperature, and humidity while reducing energy costs and improving crop quality. Modern greenhouse facilities rely on properly installed shade systems to optimize growing conditions year-round and maximize productivity. The right curtain system can transform any greenhouse structure into an efficient growing environment that protects crops from harsh conditions while maintaining optimal plant growth parameters.

What Are Greenhouse Curtains

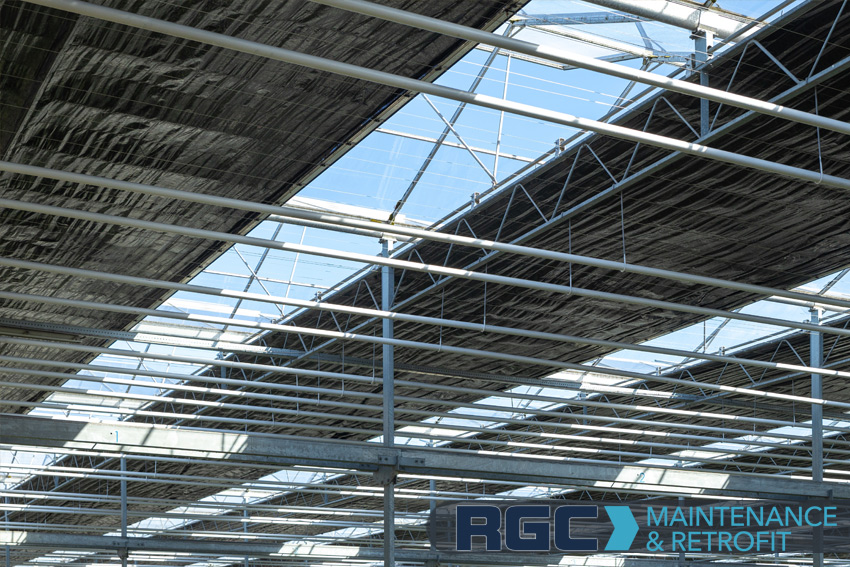

Greenhouse curtains are retractable panels of fabric installed inside the greenhouse to control light transmission and heat levels. These interior curtain systems use motorized mechanisms to open and close automatically based on environmental sensors or manual controls. Each curtain system mounts to aluminum tracks or cable systems that span the width of the greenhouse, creating uniform shading coverage across the greenhouse.

Both external shade and internal shade options provide different benefits for commercial greenhouse operations. Interior curtain systems systems are typically preferred for precise climate control, while types of exterior curtain systems offer protection from weather elements. The curtain material can include polyethylene films or knit fabrics designed to provide shade while maintaining structural integrity. Professional installation ensures proper tension and alignment for smooth curtain operation.

The curtain materials range from clear and aluminized polyester to knitted fabric screens, each offering different shading percentages and light diffusion properties. Quality greenhouse curtain systems include weather-resistant components designed for continuous operation in humid greenhouse environments. Small systems are often moved by hand, while large systems require motorized controls for efficient operation. Each curtain installation must account for the greenhouse roof design and support system requirements to ensure proper functionality.

Key Benefits of Greenhouse Curtains

Greenhouse curtains deliver multiple advantages for commercial growing operations through advanced shading and cooling systems:

- Temperature Control: Reduce peak temperatures by 8-15 degrees Fahrenheit during summer months and cool growing areas effectively

- Energy-Saving Benefits: Lower cooling costs by up to 30% through reduced heat buildup and improved greenhouse covering efficiency

- Crop Protection: Shield sensitive plants from excessive solar radiation, UV exposure, and heat stress that can cause crops to overheat

- Light Management: Control photosynthetic photon flux density for optimal plant growth while preventing light pollution

- Humidity Regulation: Reduce moisture loss and maintain consistent growing conditions with proper curtain material selection

- Extended Growing Seasons: Enable year-round production in challenging climates with blackout and shading capabilities

- Improved Crop Quality: Prevent sunscald, bleaching, and other light-related damage through precise curtain control

These benefits translate directly to increased yields, reduced operating expenses, and improved crop consistency. Growers report significant improvements in plant health and marketable produce quality after installing professional curtain systems. The cooling effect created by proper shading helps minimize stress on both crops and greenhouse equipment. Each curtain installation provides an insulating layer that contributes to shade and heat retention when needed.

Types of Greenhouse Curtain Systems

Several curtain system types serve different growing requirements and climate conditions. Understanding each option helps growers select the most effective greenhouse curtains for their specific needs and crops.

Aluminized curtain systems include knitted white polyester or aluminized polyester or acrylic materials that provide maximum heat reflection. These systems are commonly used for hot summer conditions and effectively reflect heat while controlling the amount of heat entering the greenhouse. The metallic aluminized strips create a mirror-like surface that bounces thermal radiation away from the growing area. Each curtain provides excellent shading performance for greenhouse roof protection.

Knit fabric curtain systems offer more gradual light reduction with bonded white polyester fiber construction. These greenhouse curtains create softer lighting conditions ideal for sensitive crops like lettuce, herbs, and flowering plants. The open weave knit design maintains airflow while reducing light intensity, preventing unwanted shade that can harm plant development. The curtain material allows for precise light control without completely blocking airflow.

Blackout curtain systems enable complete light control for photoperiod manipulation and day length control. Flower growers use these blackout curtains to control the greenhouse during the day and greenhouse at night cycles. The opaque materials block nearly all light transmission when fully deployed, creating artificial growing environment for plants regardless of external conditions. These curtain systems can cover and uncover growing areas completely as needed.

Climate curtain systems combine shading with insulation properties. These dual-purpose internal curtain systems reduce heat loss during cold periods and provide shade during warm weather. The reversible design maximizes energy efficiency by managing temperature and light throughout the growing season. Many systems include polyethylene components for added durability.

Perforated curtain systems balance light reduction with ventilation requirements. Materials can use fabric or plastic film with small holes throughout that allow air movement while providing consistent shade coverage across greenhouse space. These curtains provide moderate shading levels with good air circulation. The monofilament construction in some systems offers enhanced durability and easy maintenance.

Installation and Maintenance Considerations

Proper curtain installation requires precise measurements and structural assessment of the commercial greenhouse framework. The support system must handle the curtain weight plus wind and snow loads without compromising the structure. Professional installers evaluate rafter spacing from one truss and the next, glazing systems, and existing equipment before designing the curtain layout for optimal greenhouse roof integration.

Curtain systems are used with drive mechanisms that include gear motors, cables, and control panels requiring regular maintenance. The curtain panels lie flat when retracted and can bundle under each gutter or at the peak of the truss depending on system design. Installation may involve wires or nylon support cables stretched over the greenhouse framework. The drive system coordinates with existing greenhouse equipment for seamless operation.

Modern curtain installations often include retrofit capabilities for existing structures. Drive systems coordinate with vents or louvers and unit heaters or circulation fans to maintain optimal air circulation. The air above the system must remain properly ventilated to prevent heat buildup that could damage both crops and equipment. Proper curtain positioning ensures materials lay flat at gutter height when retracted.

Regular cleaning maintains optimal light transmission through the curtain materials. Dust, pollen, and humidity can reduce effectiveness over time. Automated wash systems or manual cleaning protocols keep the curtains functioning at peak performance levels. Systems are typically designed with monofilament or smooth surfaces that resist debris accumulation and provide easy maintenance access.

Quality curtain installations include backup power systems to protect crops during electrical outages. Control systems monitor greenhouse leaks and adjust curtain positions to compensate for changing environmental conditions. This prevents air trapped above the curtain from creating temperature imbalances throughout the greenhouse structure.

Climate Control and Energy Efficiency

Commercial greenhouse curtain systems work with heating, ventilation, and cooling systems to create optimal growing environments. Integrated controls coordinate curtain positions with temperature sensors, light meters, and weather stations. This automation reduces energy consumption while maintaining precise environmental conditions for consistent crop production.

Summer cooling loads decrease significantly when greenhouse curtains block excess solar radiation. The curtain system warms the air above the curtain while keeping the growing area cool through effective shading. Ventilation fans run less frequently, and evaporative cooling systems use less water. The reduced heat buildup also extends the life of greenhouse equipment and structures by preventing thermal stress on components.

Strategic curtain deployment during peak sunlight hours prevents temperature spikes that can damage crops and increase cooling demands. Unlike shading paint that provides permanent coverage, retractable curtain systems offer precise light and temperature control. Modern control systems can predict weather patterns and adjust curtain positions proactively, maintaining stable growing conditions. The shading and cooling effect helps prevent crops from overheating during extreme weather.

Winter heating efficiency improves when curtains provide insulation during cold periods. Double-layer curtain systems create air gaps that reduce the amount of cold air infiltration through the greenhouse covering. This thermal barrier can reduce heating costs by 15-25% compared to unshaded structures, providing substantial savings during Ontario’s cold winter months. The greenhouse roof benefits from additional insulation when curtains remain closed during cold periods.

Energy monitoring systems track the impact of curtain operation on overall facility consumption. Data collection helps growers optimize curtain timing and positioning for maximum efficiency. The air above the system requires proper management to prevent heat stratification that could affect crop uniformity. Proper curtain management helps cool growing areas while maintaining energy efficiency throughout the operation.

Choosing the Right Curtain System for Your Operation

Crop requirements determine the optimal shading percentage and curtain type for each application. Tomatoes and peppers typically need 30-50% shading during peak summer conditions. Leafy greens and herbs often require 60-80% shading to prevent tip burn and maintain quality. The right curtain system selection helps minimize plant stress while optimizing growing conditions.

Geographic location affects curtain system selection based on local climate patterns. Ontario growers face intense summer sun combined with cold winters, requiring versatile greenhouse curtain systems that adapt to seasonal changes. Light levels, temperature extremes, and precipitation patterns influence the curtain specifications and support system requirements.

Greenhouse orientation and glazing materials impact shading requirements. South-facing structures receive more direct sunlight and need higher shading percentages from their curtain systems. Single-layer glass allows more heat transmission compared to double-wall polycarbonate, affecting the cooling load and curtain needs. The greenhouse roof design also influences how curtains should be positioned for maximum effectiveness.

Budget considerations include initial installation costs, operating expenses, and long-term maintenance requirements for greenhouse curtains. Higher-quality curtain systems cost more initially but provide better durability and energy savings over their service life. Return on investment calculations should include energy savings, improved yields, and reduced crop losses. Each curtain installation should be evaluated based on its ability to cool growing areas effectively while providing appropriate shading levels for specific crops.

Professional Installation Services

Ruthven Greenhouse Construction provides comprehensive curtain installation and maintenance services for commercial growers throughout the Windsor-Essex region. Our experienced team understands the unique requirements of Ontario greenhouse operations and local climate challenges. We specialize in both blackout and shading curtain systems designed to optimize growing conditions.

We evaluate existing structures and recommend optimal greenhouse curtain systems based on crop types, facility design, and budget parameters. Our installation process includes structural assessment, precise measurements, and quality components designed for reliable long-term curtain operation. Each curtain system installation considers greenhouse roof design, support system requirements, and integration with existing equipment.

Our service area covers Leamington, Kingsville, and surrounding areas where greenhouse agriculture drives the local economy. We maintain relationships with leading curtain manufacturers and stay current with the latest shading technologies and automation systems. Our team ensures proper curtain positioning and can retrofit existing structures with modern shade systems for improved performance.

Maximize Your Growing Potential

Greenhouse curtains represent a critical investment in crop quality, energy efficiency, and operational success. Proper curtain system selection and professional installation ensure maximum benefits and long-term reliability. These shade systems pay for themselves through reduced energy costs, improved yields, and enhanced crop quality. The thermal mass effect created by curtain systems helps stabilize temperature fluctuations throughout the day while providing essential shading coverage.

Modern curtain systems offer precise control over growing environments, allowing operators to cool areas as needed while maintaining optimal conditions for plant growth. Each greenhouse curtain installation should be designed to work with existing equipment and greenhouse roof structures for maximum effectiveness.

Ruthven Greenhouse Construction has the expertise and experience to design and install the ideal curtain system for your operation. Contact us today to discuss your greenhouse curtains needs and discover how professional installation can transform your growing environment and boost your bottom line.

Ruthven Greenhouse Construction has the expertise and experience to design and install the ideal curtain system for your operation. Contact us today to discuss your greenhouse curtains needs and discover how professional installation can transform your growing environment and boost your bottom line.

Share This Article

Choose Your Platform: Facebook Twitter Google Plus Linkedin